| Description |

|

At EMSL Analytical, a wide variety of materials — metals, polymers, ceramics, semiconductors, and many others — can be analyzed for their elemental composition, phases, structure, and properties.

Chemical Analysis

Information about the major or trace elemental components of a sample can be obtained using state-of-the-art WDXRF (wavelength-dispersive X-ray fluorescence), ICP (inductively-coupled plasma), and AA (atomic absorption) spectrometers. Chemical compounds can be identified by GC/MS (gas chromatograpy/mass spectrometry). Residual gas analysis is an on-going effort at EMSL Analytical that includes a novel approach of glow discharge visible and infrared spectrometry, and a conventional approach utilizing quadrupole mass spectrometers.

|

|

Structural Analysis

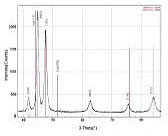

XRD (X-ray diffraction) is often used for qualitative and quantitative crystalline phase analysis at EMSL Analytical. Other techniques used for phase and structural analysis include NIR (near-infrared) and FTIR (Fourier transform infrared) spectroscopy; thin film analysis by XRD; and electron diffraction with TEM (transmission electron microscopy). Our µ-FTIR is capable of obtaining an infrared absorption spectrum from a region as small as 15µm, which makes identification of small unknown particles a much easier task.

|

XRD spectrum of an alloy sample XRD spectrum of an alloy sample |

|

Microscopy Analysis

OM (optical microscopy), SEM (scanning electron microscopy) and TEM (transmission electron microscopy) are used at EMSL Analytical for various types of microstructural analysis and phase identification. For example, particles can be identified first with PLM (polarized light microscopy) and then further verified by SEM/EDX (energy-dispersive X-ray analysis); the grain- and microstructure of alloys can be determined with TEM; the defects in semiconductors can be checked by cross-section TEM analysis; the quality of wire-bonding can be examined by SEM inspection; and the thickness of a thin film deposition can be characterized using a scanning AES (Auger electron spectrometer) to generate a depth profile.

|

|

Order Sampling Supplies

Order Sampling Supplies Request Pricing

Request Pricing Technical Questions

Technical Questions 24/7 Account Access

24/7 Account Access Email Us

Email Us